Paste filling or Back filling is a method used to dispose of mine tailings underground, to backfill underground mine stopes, or to achieve both simultaneously.

One of the key difficulties in sustaining an effective paste fill operation is to maintain a serviceable conduit in which the paste material can travel from the above ground processing plant to the specified void or stope below surface without contamination. This is most often achieved by cementing a large diameter conductor casing from surface to underground within a borehole, then suspending a replaceable wear casing inside through which the paste material can travel.

In many cases we are contacted by a new client who is experiencing water diluted paste underground. Upon conducting a desktop review and downhole camera inspection survey, we quickly identify that there is no sacrificial internal lining installed and the main bore casing has been worn away exposing underground aquifers that are introducing excess water and diluting the paste.

A common occurrence in these replaceable wear casing strings when managed poorly is the premature failure of the replaceable casing and subsequent cementing of the string into the main borehole. This can make retrieval for replacement extremely difficult or impossible, forcing the need for a smaller diameter casing to be installed within the old string, or a new hole to be drilled entirely.

The premature failure is caused by the highly abrasive paste freefalling at high velocity which produces slurry erosion in localised areas of the string. Once this erosion pattern is established, a channel will form and promote further erosion in the same region. This channel will scallop extremely rapidly until the casing breaches – typically this will result in the paste fill casing being cemented into the outer casing. If removal is possible, it will usually reveal that the majority of the replaceable casing material shows little wear other than at the localised point of failure.

Click here to see downhole camera inspection footage of worn casing due to poorly managed paste fill operations.

It has been found that the key factor in avoiding this premature wear situation is reducing the velocity of the falling paste. By ensuring that the paste material remains backed up inside the string, the corrective action is twofold:

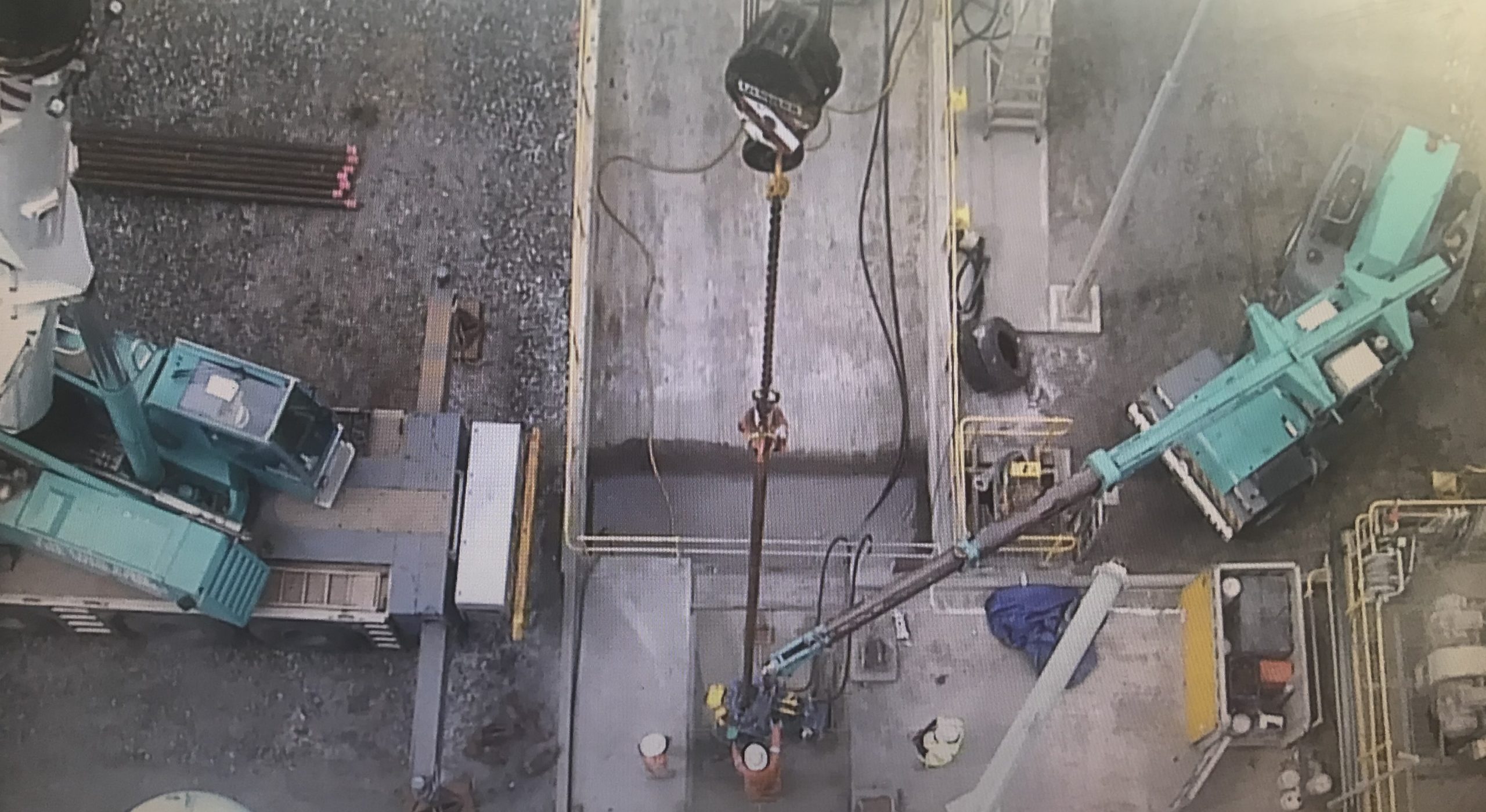

We have had tremendous success for over 20 years in making use of premium threaded oilfield casing to fulfil the requirements of such wear casing. Our unique approach to this problem has seen us involved in many paste plant casing installations for mine sites throughout the country. We have selected premium threaded oilfield casing as the material of choice for several reasons:

Typically we recommend installing a surface feeder pipe consisting of one joint of 7” casing that acts as a funnel for a smaller diameter casing. It is this smaller casing that controls paste velocity and maintains an even, laminar paste flow to avoid premature wear channelling. We typically recommend 4 1/2″ casing for the main string below the surface feeder joint however many size options are available.

Alternative surface feeder casing:

We typically recommend 4 1/2″ casing for the main string below the surface feeder joint. There are many wall thicknesses and grades available for the 4 1/2″ casing however the common size that will typically be available is as follows:

Alternative sizes available (less common):

As is the case with any surplus material, used premium threaded casing is subject to availability. This means the wall thickness, grade and thread options will vary frequently and will need to be confirmed at the time of order placement.

If the quantity of casing required is high enough, specified mill runs can be ordered with wall thicknesses on the casing as great as 15mm in even higher tensile grades. Mill orders can take in the vicinity of 6 months to land into ports in Australia from time of order.

Paste fill casings are most efficient when installed in a vertical orientation rather than set at an inclination. Inclined casings will preferentially wear on the lower side of the casing material and reduce the operating life of the string. Additionally, the installation and removal of the string is significantly more efficient when servicing a vertical hole.

A common industry misconception in regards to Paste Fill boreholes is to install the borehole on a shallow angle to control paste velocity. AGE Developments has encountered this at numerous mine sites around the world with the same resultant preferential localised wear on the low side of the bore casing with the remainder of the casing remaining untouched. Installing threaded replaceable wear casing inside angled holes is achievable however installation and removal timeframes are greatly increased. A far better way to control paste velocity and thus wear is by reducing diameter of the casing and maintaining laminar pipe full fill regimes.

AGE Developments provides a complete design, manufacturing, installation and retrieval turnkey service for Paste Fill bores with extensive track history.

To find out more or to discuss any specific needs you have, contact AGE Developments.

© 2024 Age Developments | Privacy Policy

Website by Roobix