Aquifer Storage and Recovery (ASR) or Aquifer Injection Control (AIC) is a method of enhancing water recharge (MAR – Managed Aquifer Recharge) to underground aquifers by gravity feeding or pumping excess water into the aquifers for later use in times of peak demand or simply a method to store unwanted or surplus water stocks.

ASR is a low-cost alternative to store water (compared to surface storages) and can minimise evaporative water loss.

During injection, the water in the injection column is controlled to prevent air from being entrained or trapped in the fluid flow and carried into the aquifer. Entrained air can adversely affect the recharge efforts, through air-fouling, bio-fouling and calcite formation, blocking the sustained flow of water into the aquifer in the longer term.

There are many options available for aquifer injection control based on the desired level of control and the intended application.

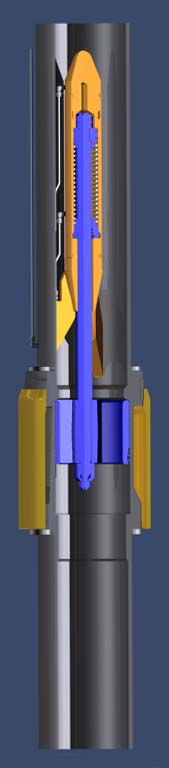

The AGE ASR valve is the ultimate in injection control that also allows aquifer fluids to be injected or pumped to meet either production requirements or to back flush where an injection bore is susceptible to regular fouling due to mineralised deposits forming within the bore causing clogging issues.

The ASR valve is controlled by the surface hydraulic control system (SCS) and allows the same user functionality as the FCV system with the addition of the recovery or back flush cycle. In this mode of operation, the annular ASR valve is modulated fully closed and aquifer fluids are pumped through the valve by means of an electric submersible pump installed below the ASR valve.

To return to injection mode, the pump is stopped and the SCS is returned to injection mode modulating the ASR valve according to the set parameters.

Injection is accommodated through the valve by means of radial injection ports that are specifically shaped to obtain proportional control of injection flow rates. Injected water is then deflected downwards by the injection shroud ensuring that erosion of bore casing does not result.

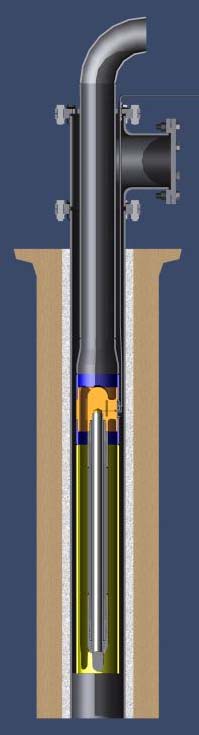

The ASR Valve can be deployed downhole on either a traditional pump riser column or for greater efficiency on an inflatable packer similar in nature to the AGE Riserless Pump Packer system.

The simplest method allowing basic unmanned and unmonitored control of the injection fluid is to employ a pneumatic packer at the bottom of the injection column or simply suspended into the bore casing.

The packer is inflated with air, nitrogen or water to control the orifice annulus between the packer element and the outer shroud thus controlling the injection flow rate and subsequent system back-pressure.

FCP Packer inflation control can be achieved by various methods ranging from manual surface adjustment through the inflation control line or automated adjustment via the inflation line and a PLC based on user set defined points.

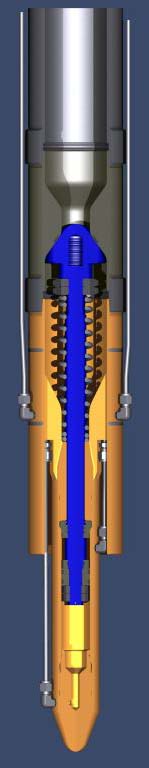

Stepping up, the next option is to employ a downhole Flow Control Valve (FCV) that can be either manually or automatically (via PLC) controlled from surface by means of the surface control system (SCS).

This system allows the user to control the injection pressures and flow rates to desired levels and alarm when the injection system is at fault. Typically the system is configured by means of a PLC that will allow the user to specify the desired injection flowrate provided the injection pressure remains within a set band of allowable pressures. The valve will modulate open and closed by way of surface pumps, valves and controls within the SCS trying to achieve the desired injection flow rate.

If the system falls outside of the desired injection pressures, the system can be configured to alarm such that the required action can be taken. Such faults may be:

1. FCV modulated fully open with injection pressures above maximum set pressure and desired injection flow rate not obtained. This fault would be caused by a blocked or fouled bore that is not taking the desired flow rate.

2. Injection pressure falling below minimum set point. This fault signals a problem with either the FCV, SCS or PLC controls resulting in injection water possibly cascading into the bore and entraining air which can result in subsequent air-fouling, bio-fouling or calcite formation.

All water bore equipment is manufactured from stainless steel materials and potable water grade rubber compounds compliant to AS/NZS:4020.

Below is a list of injection bore clients AGE Developments have successfully worked with:

|

|

To find out more or to discuss any specific needs you have – be it for off the shelf equipment or custom designed equipment, contact AGE Developments.

© 2024 Age Developments | Privacy Policy

Website by Roobix